Using Deep Learning Software for Contaminant Analysis

Contaminant analysis is a crucial segment of the manufacturing workflow whether you are conducting quality assurance or quality control (QA/QC). If defects or contaminants are detected in your finished products it can indicate potentially hazardous process irregularities that could prove detrimental to consumers if not corrected. This applies to all areas of manufacturing, from construction materials through to pharmaceuticals.

The challenge in modern QA/QC is that the manufacturing environment is increasingly driven by stringent efficiency requirements in the name of productivity. Guaranteeing product quality often runs contrary to pushing the bottom line, meaning contaminant analysis must be carried out quickly as well as effectively.

Automation and digital integration are central to the push for greater productivity in manufacturing environments. The concept of automating production typically brings to mind the robotic arms of assembly lines, but manufacturers are just as interested in software solutions that accelerate critical processes throughout the manufacturing pipeline. Deep learning is on such solution.

What is Deep Learning?

Deep learning is a subset of machine learning based on large neural networks modelled loosely on the human brain. It is a complex concept based on hierarchical feature learning using hand-labelled training examples. A neural net composes thousands of interconnected process nodes organized into layers. Early networks were limited to depths of just a few layers, but modern neural nets may extend to depths of as many as 50.

The aim with deep learning is to teach software how to recognize features of interest at multiple levels of abstraction. Simple algorithmic image analysis includes pass/fail software that detects when a part has deviated from user-defined specifications. But this relies on human intervention and the initial establishment of set limits.

Deep learning software is increasingly focussed on learning complex functions and automatically mapping inputs to outputs based purely on data derived from the system. Put into the context of contaminant analysis, deep learning software learns how to detect defects by algorithmically running through a hierarchy of simple concepts interspaced throughout the neural net. But how can this help drive process efficiency?

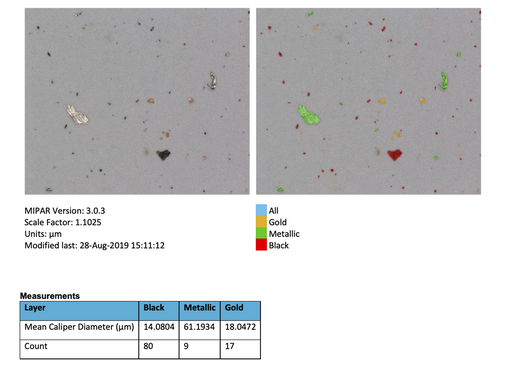

Contaminant Analysis with MIPAR