Grain Structure Analysis for Metals & Alloys

|

An important facet of materials work is grain structure analysis for metals and alloys. Whether it is for manufacturing purposes, industry research and development, or quality assessment and regulation, grain structure analysis is central to much of the data collection in material science laboratories.

The Basics of Grain Structure Analysis

Performing grain structure analysis in material laboratories requires complex and precise processing to accomplish research and industry goals. Such objectives include assessing various grain sizes and their distribution. Delving into the intricacies of grain structure analysis, especially in metals and alloys, gives insight into how these materials can be used for practical purposes.

Titanium, steel, copper, aluminium, and ceramics are some of the metals and alloys that MIPAR has developed grain structure analysis software for. These advanced materials are widely applicable to the science and technology industries. From construction of physical machine components to use in inventive products, the grain structure of metals and alloys contribute to much of their versatile physical and chemical properties.

Automated Image Analysis of Grain Structure

Traditionally, separate analytical software or manual techniques is needed to gather grain structure data. This can be an inefficient and time-consuming process. However, MIPAR’s development of automated image analysis software has streamlined industrial material science work, particularly grain structure analysis, through enhanced visual data collection.

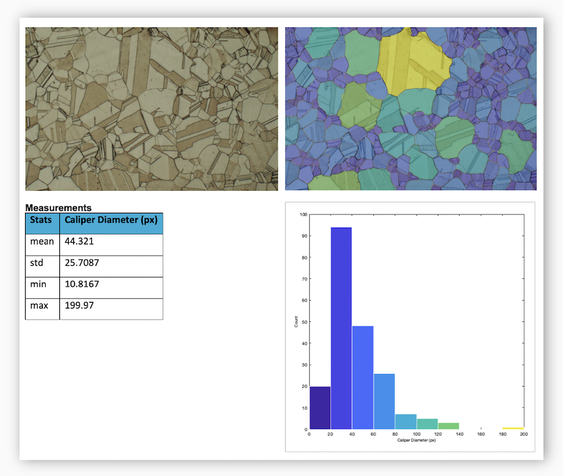

MIPAR image analysis software offers fully automated grain size solutions, the ability to analyse micrographs without continuous reference to a microscope, and the ability to run samples of data in batch sets. Additional benefits of MIPAR automated grain structure analysis systems include the generation of statistics and comprehensive reports to easily and efficiently share data across research and industry networks.

The incorporation of cutting-edge deep learning technology simplifies grain structure analysis into straightforward and discrete steps: trace, train, and apply. With this intuitive user interface, MIPAR’s grain structure analysis solves challenges like low contrast and noise in grain imaging as well as detecting grains while ignoring twins, all in a matter of seconds.

Titanium, steel, copper, aluminum, and ceramics are some of the metals and alloys that MIPAR has developed grain structure analysis software for. These advanced materials are widely applicable to the science and technology industries. From construction of physical machine components to use in inventive products, the grain structure of metals and alloys contribute to much of their versatile physical and chemical properties.

Grain Structure Analysis at MIPAR