How to Automate Powder Imaging & Analysis

Powder analysis is frequently used in various industries, including pharmaceuticals, food processing, additive manufacturing, and powder metallurgy. This technique is conducted to look at powders' chemical composition, flow properties, particle shape, and particle size distribution, all of which are essential for quality control and optimizing manufacturing processes. However, manual powder analysis can be challenging, time-consuming, and prone to human error. Therefore, in this blog post, we look at the importance of automating powder imaging and analysis and how it can overcome the challenges of manual methods.

Importance of Powder Imaging and Analysis in Various Industries

Powder analysis is vital in industries where the quality and consistency of powder products directly impact the end product's quality. One example is additive manufacturing, where precise control over powder characteristics is crucial for producing the required mechanical properties in 3D-printed objects. Another example is the pharmaceutical and food industries; there are various factors that influence the quality and efficacy of formulas and final products. Additionally, in powder metallurgy and mechanical parts manufacturing, understanding the powder properties is crucial for optimizing processes like compaction and sintering, ensuring the desired product quality.

Challenges in Manual Powder Analysis

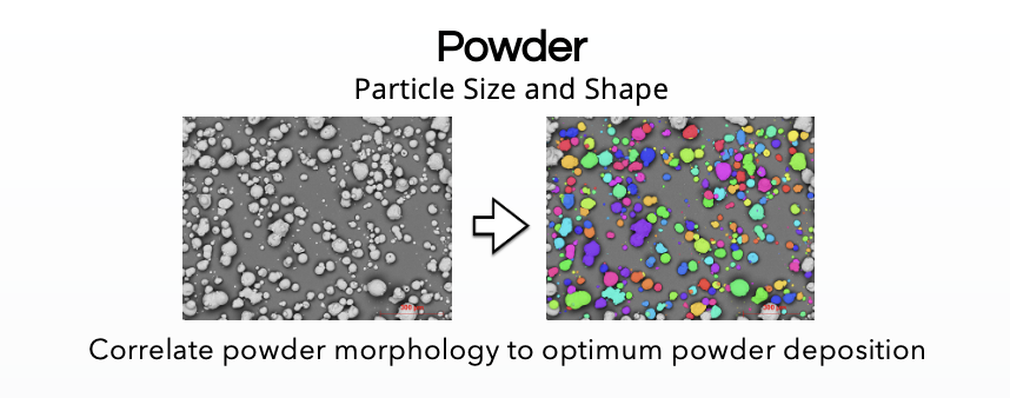

Manual powder analysis can be tedious. It requires an expert to visually examine powder samples under microscopes or with specialized instruments like sieves. Common limitations include low throughput, operator fatigue or error, and subjectivity. Additionally, some powder properties, such as particle shape, are difficult to assess accurately using manual techniques. Therefore, there is a pressing need for automation in powder imaging and analysis to overcome these challenges and improve efficiency and accuracy.

The Need for Automation in Powder Imaging and Analysis

Automating powder imaging and analysis offers several advantages over manual methods. Firstly, it eliminates human errors and biases, which ensures consistent and reliable results. Secondly, automation enables high-throughput analysis, allowing large numbers of samples to be processed in a shorter time. Finally, automated techniques comprehensively characterize powder properties, including density, flow properties, particle shape, and size distribution. As you can see, by implementing automation, industries can enhance product quality, optimize manufacturing processes, and improve overall efficiency.

Automated Image Analysis Techniques

Dynamic Image Analysis (DIA): Dynamic image analysis is a technique that involves capturing high-speed images of particles in motion. By analyzing these images, DIA provides valuable information about particle size distribution, particle shape, and flow properties. This technique is beneficial for analyzing powders with complex particle shapes or fragile structures.

Automated Static Image Analysis: Automated static image analysis techniques capture images of stationary particles. These images are then processed using specialized software to extract information about particle size, shape, and other properties. Automated static image analysis is widely used for routine powder analysis due to its simplicity and accuracy.

Software Solutions for Automated Powder Imaging & Analysis