Using Image Analysis to Detect the Root Cause of Defects

Root cause analysis (RCA) in materials science is an investigative process critical for identifying the fundamental reasons for defects in materials. This methodical approach is essential for pinpointing the origins of material failures, such as microstructural anomalies or comprehensive procedural deficiencies. The primary objective of RCA is to diagnose and resolve the core issues that lead to material defects, thereby preventing their recurrence.

Material defects can manifest in various forms, including variations in density, composition, or mechanical properties. Often, these defects result from a complex interplay of intrinsic and extrinsic factors, such as processing errors, design shortcomings, or unanticipated environmental stresses. RCA delves beyond the immediate symptoms to unearth and rectify the root problems.

Image Analysis Techniques in Defect Detection

The RCA process in materials science requires a detailed examination of the defective material, the conditions of its failure, and its entire lifecycle from conception to breakdown. This investigation typically necessitates collaboration across various disciplines, uniting the expertise of materials scientists, production engineers, and quality control analysts.

Several advanced techniques are employed in the application of image analysis in materials science:

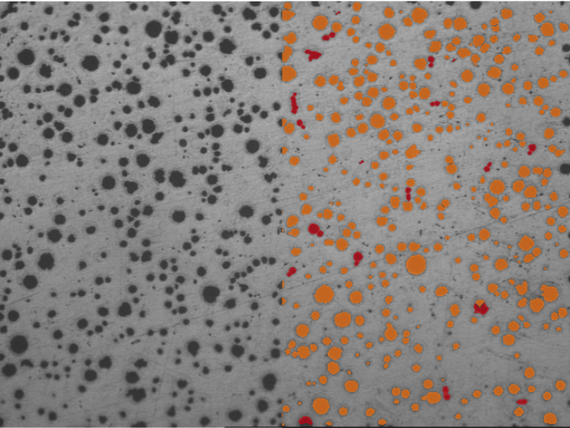

High-Resolution Imaging: Utilizing high-resolution cameras and microscopes, this technique captures detailed images of material surfaces to detect micro-scale defects that could precipitate failure.

Machine Learning Algorithms: We train these algorithms to recognize patterns indicative of defects, which enables automated detection and classification of faults in materials.

Computer Vision: This technique processes images to extract contours, which is critical for identifying anomalies in material textures and structures.

Deep Learning: Convolutional neural networks, a deep learning subset, are exceptionally adept at processing the vast data in images to identify complex defect patterns.

Determining Defect Causality Through Image Analysis

Understanding how and why a defect has occurred is a complex task that requires more than just detecting the defect itself. Image analysis provides detailed visual evidence that can be correlated with processing conditions, material properties, and environmental factors, thus aiding in this comprehensive analysis.

Incorporating RCA early in material design and production yields significant benefits. Early detection and correction of defects can reduce waste, improve safety, and enhance the final product's performance. Moreover, understanding the root causes of material defects is crucial for refining production processes, leading to better quality control and product reliability.

Integrating Image Analysis into Quality Control

Real-time monitoring of materials during production is made possible by integrating image analysis into quality control systems. Automated image analysis systems can swiftly identify defects as they occur, which is crucial for the immediate rectification of production issues. This real-time feedback loop is essential for maintaining the manufacturing process's integrity and preventing the escalation of defects.

Conclusion