How to Automate Manufacturing Defect Analysis

Defect analysis in manufacturing is critical in maintaining product quality and ensuring optimal performance throughout a product’s lifecycle. The process involves identifying, analyzing, and addressing product defects during the manufacturing phase, safeguarding against subpar products reaching the consumer.

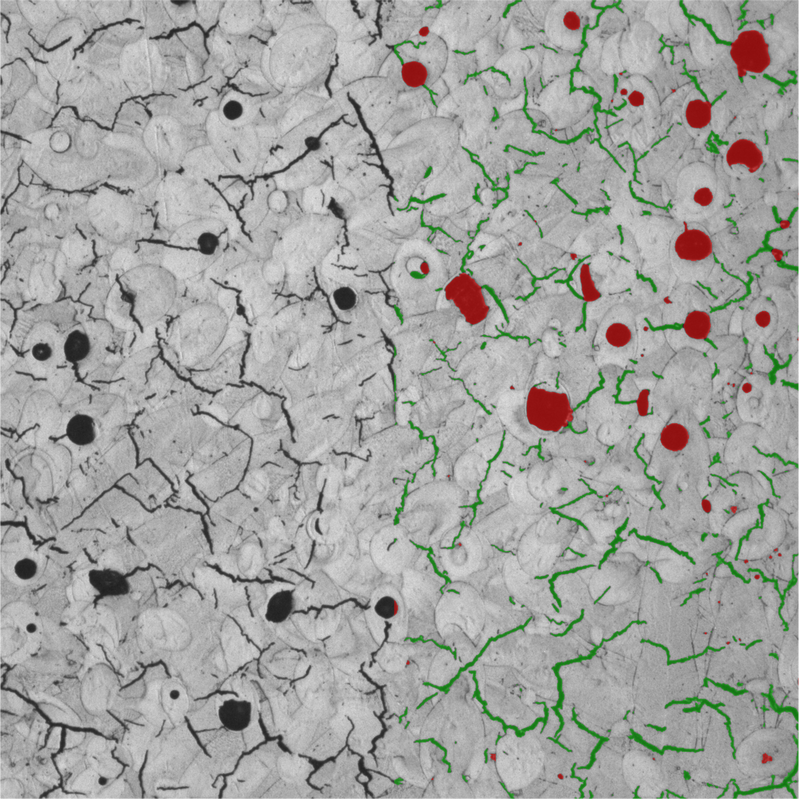

Automation in defect analysis has emerged as a pivotal strategy in enhancing the efficiency, accuracy, and consistency of identifying and addressing manufacturing flaws. Manufacturers can significantly elevate their quality assurance and control mechanisms by integrating machine vision, automated defect detection software, artificial intelligence, and various analysis techniques.

Machine Vision: A Gaze into Flawless Manufacturing

Machine vision systems utilize digital camera technology and image analysis to scrutinize product surfaces and dimensions during manufacturing, detecting defects by ensuring products adhere to specific parameters. High-resolution imaging and a dynamic range of grayscale images enable these systems to discern even minute discrepancies in product quality. Integrating artificial intelligence (AI) software further empowers the system to determine product defectiveness based on calculated parameters, ensuring a meticulous and swift defect analysis.

Automated Defect Detection Software: Real-time Quality Assurance

Automated defect detection software provides a robust solution applicable to many pass/fail tests and production processes in discrete manufacturing. Offering real-time data delivery, manufacturers can identify and address defects instantaneously. The software development behind these systems enables in-depth, visualized reporting, providing manufacturers with a comprehensive insight into their processes. This facilitates swift analysis and implementation of corrective actions, minimizing disruptions and ensuring a steadfast production line.

AI and Industrial Computed Tomography: Unveiling Hidden Defects

Amalgamating artificial intelligence and industrial computed tomography or 2D X-ray technology unveils defects that remain concealed during conventional inspection. Especially pertinent in complex manufacturing processes, this technology illuminates hidden problem areas within components, ensuring uncompromising stability and functionality. The rapid and reliable evaluation of 3D data during inline inspection ensures defective components are identified and addressed promptly, safeguarding the integrity of the value chain.

Defect Detection System: Merging Quantity with Quality

Utilizing computer vision powered by deep learning, defect detection systems automate defect detection processes, ensuring a harmonious balance between quantity and quality in manufacturing. These systems, capable of detecting defects with human-level accuracy or superior, ensure quality inspection is not compromised amidst automation. By identifying defects precisely, these systems uphold product quality while ensuring that manufacturing processes remain unhindered.

Porosity Analysis: Ensuring Structural Integrity