How Can MIPAR Help with Grain Structure Analysis?

Grain structure analysis is a staple of materials science. It factors into routine manufacturing processes, aiding in quality assurance and quality control (QA/QC) while also providing vital insights into the mechanical properties of new metallurgical systems. There are various methods used for the analysis of grain size, number, and so on, enabling a comprehensive understanding of the phases that comprise crystalline materials like ceramics and metal alloys, but they generally fall under the category of digital microscopy. Digital grain structure analysis is preferred due to its accuracy, cost-effectiveness, and processing speed. However, the reliability of any automated solution is utterly dependent on the quality of your grain measurement software. This blog post will explore automated grain structure analysis in more detail before introducing some proprietary MIPAR solutions that could help you with your R&D.

What Methods Are Used for Grain Characterization?

Traditional methods for grain characterization include the Intercept Method and the Chart Comparison approach. While both methods have their advantages, they may be less accurate and more time-consuming than more advanced techniques like automated image analysis. As a result, researchers have turned to cutting-edge tools like high-resolution imaging coupled with deep learning algorithms to improve the speed, accuracy, and efficiency of grain structure analysis.

Applying Deep Learning to Grain Structure Characterization

Deep learning algorithms have revolutionized various scientific fields, including materials science. By training neural networks to recognize patterns and structures within complex data sets, researchers can obtain more accurate and reliable grain structure analysis results. These algorithms can also process large volumes of data more quickly than traditional methods, making them an ideal choice for high-throughput applications.

MIPAR Grain Structure Solutions

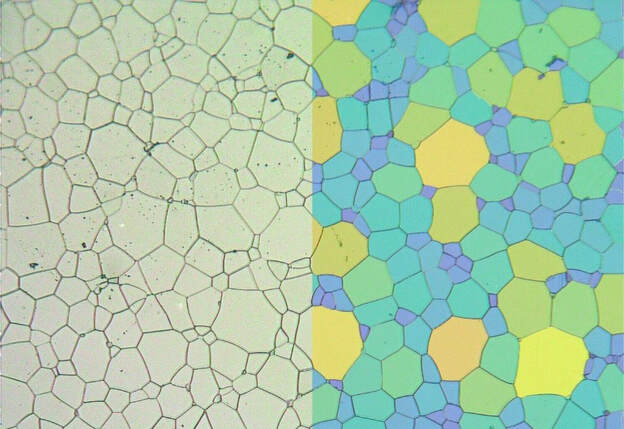

MIPAR has developed a suite of deep learning-based solutions for automated grain structure analysis in a range of materials. Each solution is tailored to specific material types, adhering to the ASTM E-112 standard for grain size measurement:

Titanium: MIPAR's fully-automated Ti grain detection and measurement system can process single images or entire sample batches, delivering fast and accurate results.

Steel: This fully automated grain-size solution for steel alloys complies with the ASTM E-112 standard. MIPAR's software can analyze micrographs directly from the microscope or process sample data sets in batches. It generates a grain size distribution and accompanying data statistics, with fully integrated reports for easy data sharing.

Copper: Similar to the steel solution, MIPAR's copper alloy grain size measurement tool is fully automated and adheres to the ASTM E-112 standard. It can analyze micrographs and process sample data sets in batches, providing grain size distribution and data statistics.

Aluminum: MIPAR's aluminum grain size analysis solution is also fully automated and complies with the ASTM E-112 standard. It can analyze micrographs and process sample data sets in batches, generating grain size distributions and data statistics.

Ceramics: Designed for sintered metal grain size analysis, this fully automated solution follows the ASTM E112 standard. It can analyze micrographs directly from the microscope or process sample data sets in batches.

The Advantages of Deep Learning Algorithms in Materials Science

Deep learning algorithms offer numerous benefits to materials science, including enhanced accuracy, processing speed, and the ability to handle large data sets. These algorithms are particularly well-suited for grain structure analysis, as they can identify subtle patterns and structures that may be difficult for traditional methods to discern. By leveraging the power of deep learning, researchers can obtain more reliable and detailed information about a material's microstructure, ultimately leading to better-informed decisions regarding material properties and performance.

Choose MIPAR for Cutting-Edge Grain Structure Analysis