|

|

|

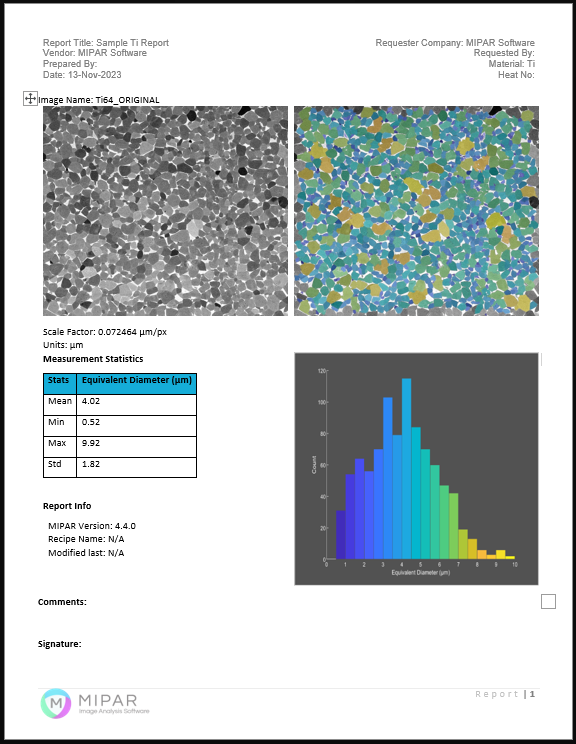

Titanium Grain Size

Automation Focused

|

Resources

|

Check Out Our Products

MIPAR Base: our core product to analyze images from almost any source. Extensions enable Deep Learning models, Word reports and 3D data analysis. MIPAR Base Page >> |

Microscope Software: capture, analyze and report all in a single workflow with MIPAR Live. Check to see if your camera is supported. MIPAR Live Page >> |

Compliance Software: analyze, report, and approve in a 21 CFR Part 11 or GMP Annex 11 compliant environment with traceability. MIPAR Checkpoint Page >> |

MIPAR APIs: tools to help integrate MIPAR detection and measurement solutions into other software applications and workflows. APIs Page >> |

CallGive us a call

Mon-Fri 9am-6pm EST +1-614-407-4510

|

MessageTell us how we can help!

|

ChatChat with us

Mon-Fri 9am-6pm EST |